Grinding

Ripley Machine is an ISO 9001:2015 Certified machine shop based in Ripley, New York that specializes in Centerless and Internal Grinding. We have been an industry leader for grinding services since the 1950s. Our operators in our grinding department have an average of 20 years in grinding. We utilize the experience to offer the highest quality grinding service available. We couple this high quality with a true commitment to service and competitive pricing. Our lead times and prices are often significantly better than our competition. We also utilize various logistics avenues that enable us to serve the entire United States as well as portions of Canada. Our location is the only one within a 120 mile radius of New York with centerless and internal grinding capabilities.

We take great pride in our ability to communicate and work flexibly with our customers to deliver them the best possible products. Once we receive the product requirements, we are able to deliver with a quick turnaround time. Please feel free to call or email us for assistance on your next grinding project. Our shop is ready to serve any of your grinding needs with our experienced staff and high-quality equipment.

What is (CNC) Grinding?

(CNC) grinding is a process that uses a rotating grinding wheel to remove material. The process works by removing small amounts of materials, such as aluminum or stainless steel, with a rotating high-speed wheel being used as a cutting tool. Ripley Tool & Machine can grind a variety of common materials, including aluminum, stainless steel, brass, steel alloy, HDPE, PEEK, ULTEM, forgings, castings, and more to design parts for various industries.

There are many types of grinding, including cylindrical, internal cylindrical grinding, centerless grinding (including in-feed grinding, thru-feed grinding and bar grinding) and surface grinding. We provide all of these services, and you can read more about them below.

Benefits of Grinding

There are many advantages to using CNC grinding as a part of manufacturing your method. Machines are able to run without interruption, allowing for production of large quantities of parts. Additionally, they are able to produce high precision parts with accuracy even at high speeds. Operating efficiently also decreases the amount of waste produced. The ability to run uninterrupted and produce precision parts with high accuracy and at high speeds means we are able to easily manufacture large quantities of products for customers who need to order in bulk.

Types of Grinding

Internal Grinding

We are able to grind straight or taper bores

We can grind parts with a bore diameter between .625” and 9” with a length up to 7”

For jobs requiring a ground taper bore, we use a corresponding taper gage (typically customer supplied although we have qualified vendors to provide if necessary). We follow a standard procedure to determine the gage standoff which determines the bore diameter

We record stand off dimension and a copy of the bluing strips (used to ensure correct taper) for each part ground

For jobs requiring a straight taper bore, we typically use certified dial bore gages set with gage blocks and a height gage. When lead time and quantity warrant we will purchase other specialize measuring equipment.

Thrufeed Centerless Grinding

Thrufeed is best utilized on higher quantities where the ground diameter is the largest diameter (no shoulders). The part is then able to pass through the grinding zone.

Parts with a diameter as small as .063” and up to as big as 2-1/2”

Tolerances as close as .0003” and surface finishes better than 8 Ra

For high production jobs, we have the ability to utilize automatic feeders and air gaging

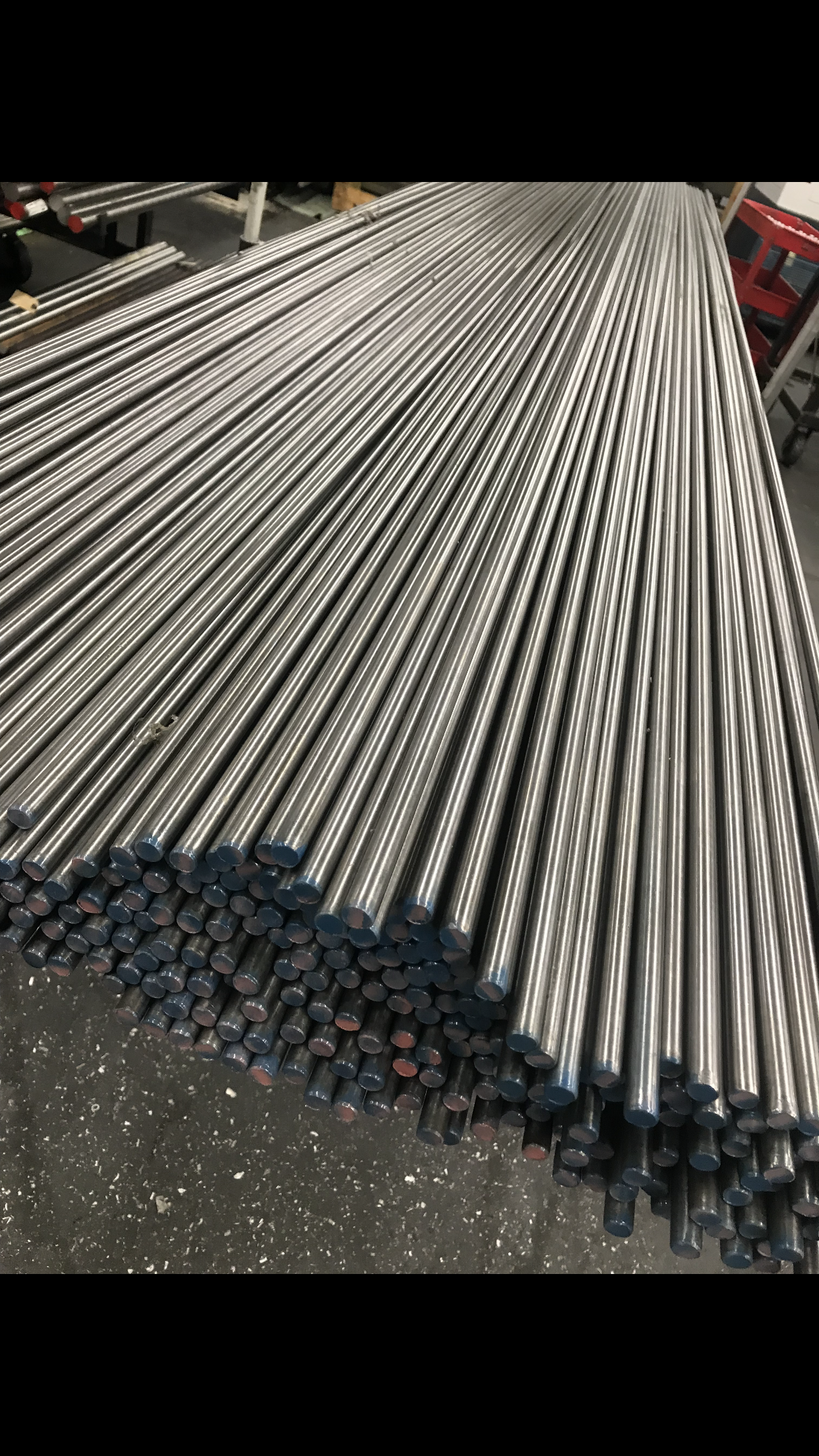

Centerless Bar Stock Grinding

Capability to grind bars up to 1” diameter at lengths up to 14’ long.

Experience in grinding numerous materials including: tool steel, stainless steel, aluminum, Hastelloy, brass, copper, plastic and many more

We often grind bar stock for Swiss machines to fit an existing collet and/or guide bushing to save cost and lead time of new work holding. We also grind bar stock to finish diameter to save cycle times. This includes grinding to major diameters for parts with an external thread.

We are able to grind customer supplied material or use one of our qualified vendors to purchase and supply the material ourselves.

Infeed Centerless Grinding

When your part has a geometry that does not allow for it to pass through the grinding area, infeed centerless grinding can be used to essentially “plunge” grind the diameter to size. This method is also useful on parts that are out of round or for small quantities.

Our infeed grinder can grind up to 4” in diameter and up to 6” long. We can hold tolerances to .0003” and surface finishes better than 8 Ra

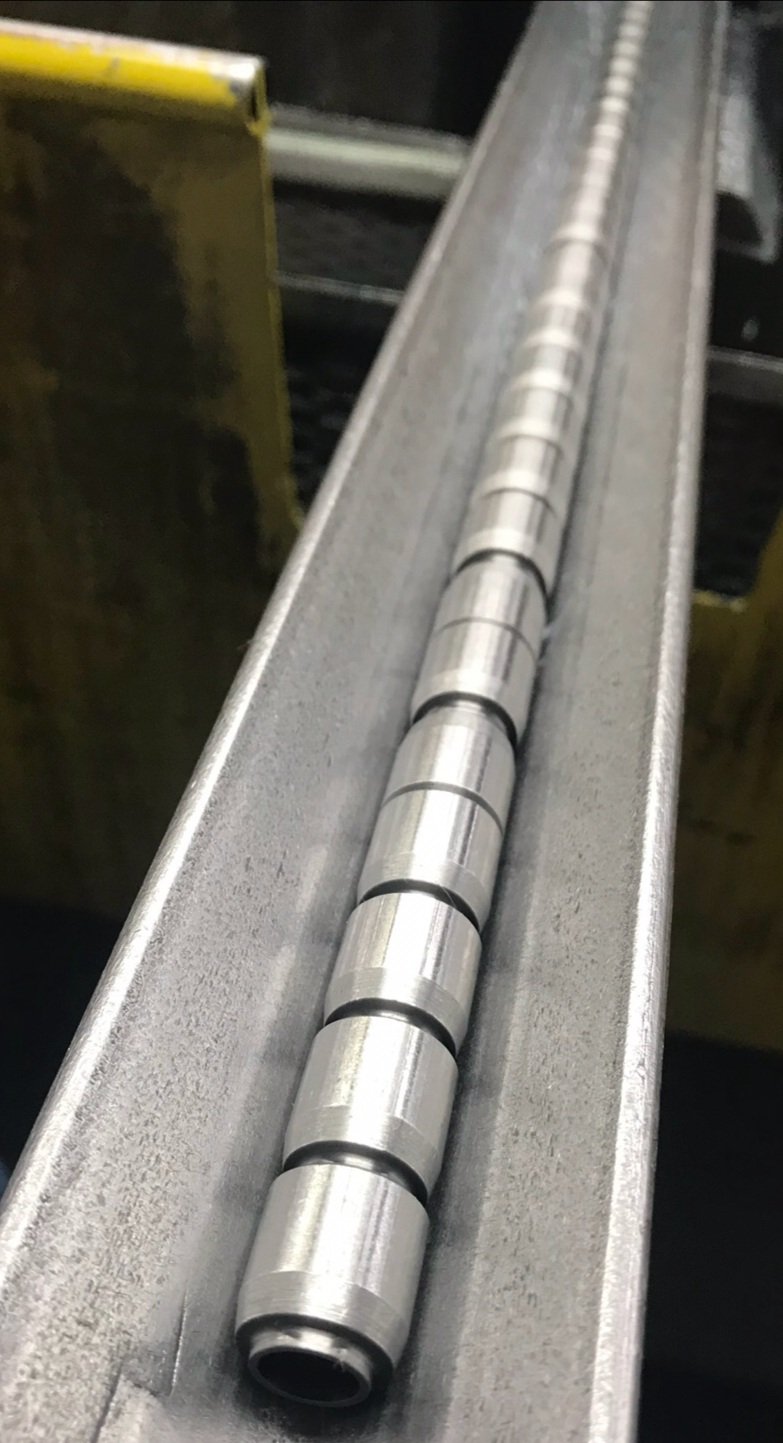

Center Grinding

We have the capability to grind between centers with our CNC Grinder

We can grind parts up to 20” long and up to 3” in diameter

We have the ability to grind multiple diameters to ensure concentricity between them

Industries Served

Ripley Machine & Tool serves companies across a variety of different industries. These are just some example of the industries we serve and the services we provide for our customers

Common Materials That We Machine

Aluminum | Stainless Steel | Brass | Steel

Plastics | And Much more!