CNC Milling

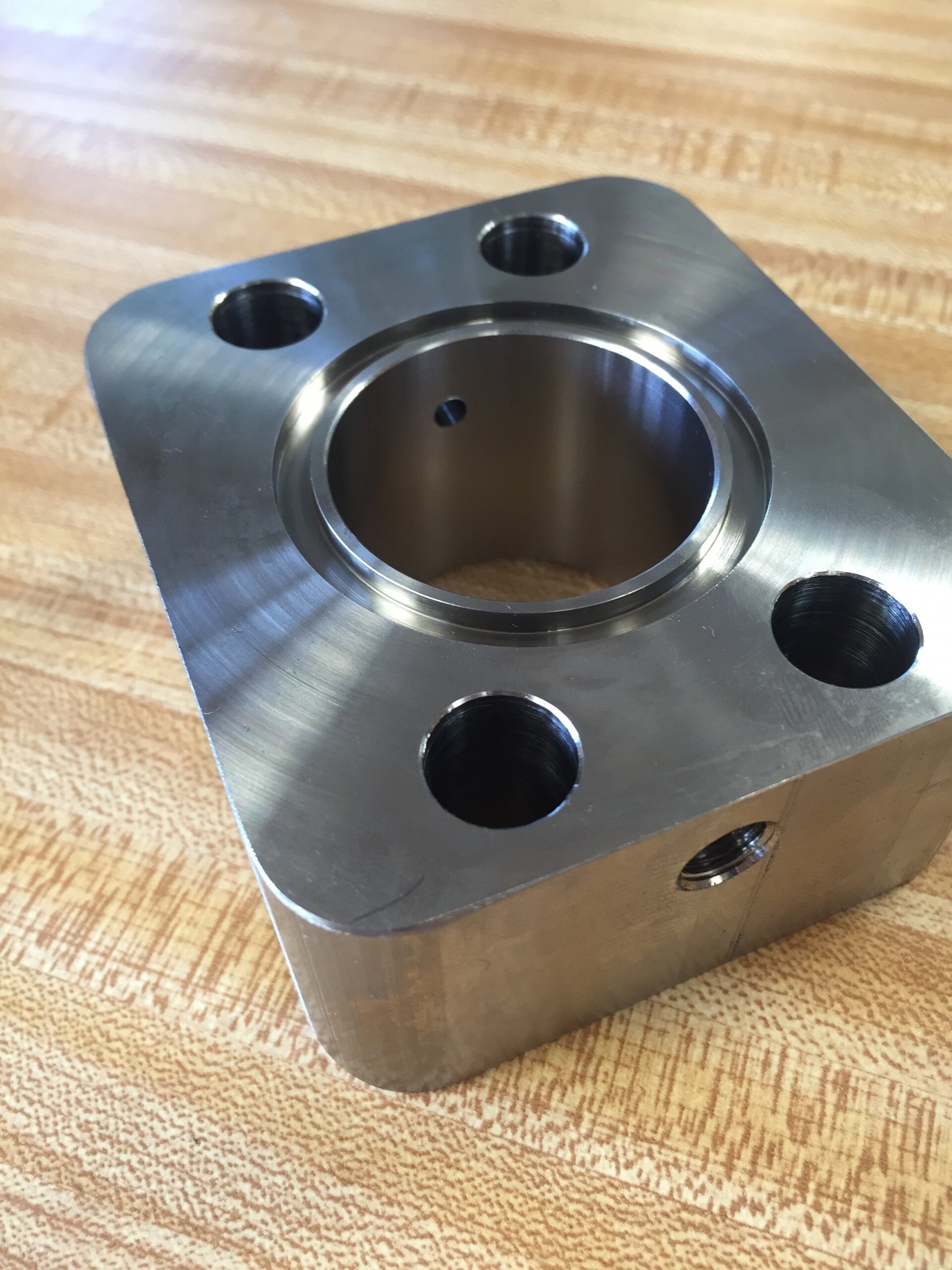

Ripley Machine & Tool is a machine shop in Ripley, New York that has produced innovative manufacturing solutions in CNC machining since the 1950s. Among our many machining services, we specialize in CNC milling. CNC milling is a critical manufacturing process at Ripley Machine & Tool. Our experts have over 40 years of combined experience in machining simple brackets, castings, valve components, and more.

We understand that in order to move forward with your product development process or get your equipment back online you need parts fast, and exact to your print or 3D model. Ripley Machine returns quotes in under 6 hours and has a standard delivery of milled parts in 10-15 workdays. We machine parts for various industries including pumps and valves, trucking, fluid control, oil and gas, electronics, medical and more. Typical parts that we machine include valves, motor mounts, enclosures, and custom equipment replacement parts.

Ripley Machine & Tool works closely with customers to get a detailed understanding of their product requirements. We pride ourselves on our communication and flexibility when it comes to working with our customers to create the best possible product with a quick turnaround time. To get started with your project, click the “Get a Quote'' button below and fill out the brief form. We look forward to working with you and appreciate your support of custom CNC milled parts machined in the U.S.A.

What is CNC Milling?

CNC milling is a machining process that is used to manufacture various parts through subtraction machining. The process shapes various materials, such as metals or plastics, by keeping them stationary and rotating cutting tools around them. The material is mounted to a table, while the cutting tools are mounted on a rotating spindle that can rotate on many axes to allow for more freedom of movement, and thus more capabilities for creating complex shapes. Ripley Machine & Tool can machine materials including aluminum, stainless steel, brass, steel alloy, HDPE, PEEK, ULTEM, forgings, castings, and more to design parts for various industries.

Benefits of CNC Milling

CNC milling offers many benefits and advantages. The process uses sophisticated CAD-CAM software to produce parts with precision, including complicated shapes, and does so efficiently due to its faster production speed. Milling machines also reduce production costs. Its precision, high speed capabilities, and low cost allow for it to be able to easily reproduce parts, making it suitable for creating large batches of products. This is ideal for customers looking to order pieces in bulk. Lastly, CNC milling is a safe process, and our experienced milling experts are always on site to ensure safety throughout the manufacturing process.

Industries Served

Ripley Machine & Tool serves companies across a variety of different industries. These are just some example of the industries we serve and the services we provide for our customers:

Common Materials That We Machine

Aluminum | Stainless Steel | Brass | Steel

Forgings & Castings | And Much more!