CNC Horizontal Milling for Valve Components

For over 50 years Ripley Machine has been an industry leader in CNC horizontal milling for valve components. Our team has experience and an understanding of the industry and how the components that we are machining function. This enables us to work closely with our customers to ensure that we are manufacturing their products in an efficient manner and to the utmost quality.

As the years passed, we invested in improving our processes, equipment and technology to ensure we can better serve our customers. We recently made a large investment in a Kitamura HX-300iG Horizontal CNC Mill with pallet changing. This investment is already allowing us to better serve our customers in the valve industry.

CNC Milling for a Wafer Style Check Valve

These check valve components were one of the first jobs we machined on our new Kitamura HX-300iG.

Within the first month of the purchase, we changed how we processed a component for a wafer style check valve. We previously processed the part in four operations on four different machines. One of the operations required extensive handling.

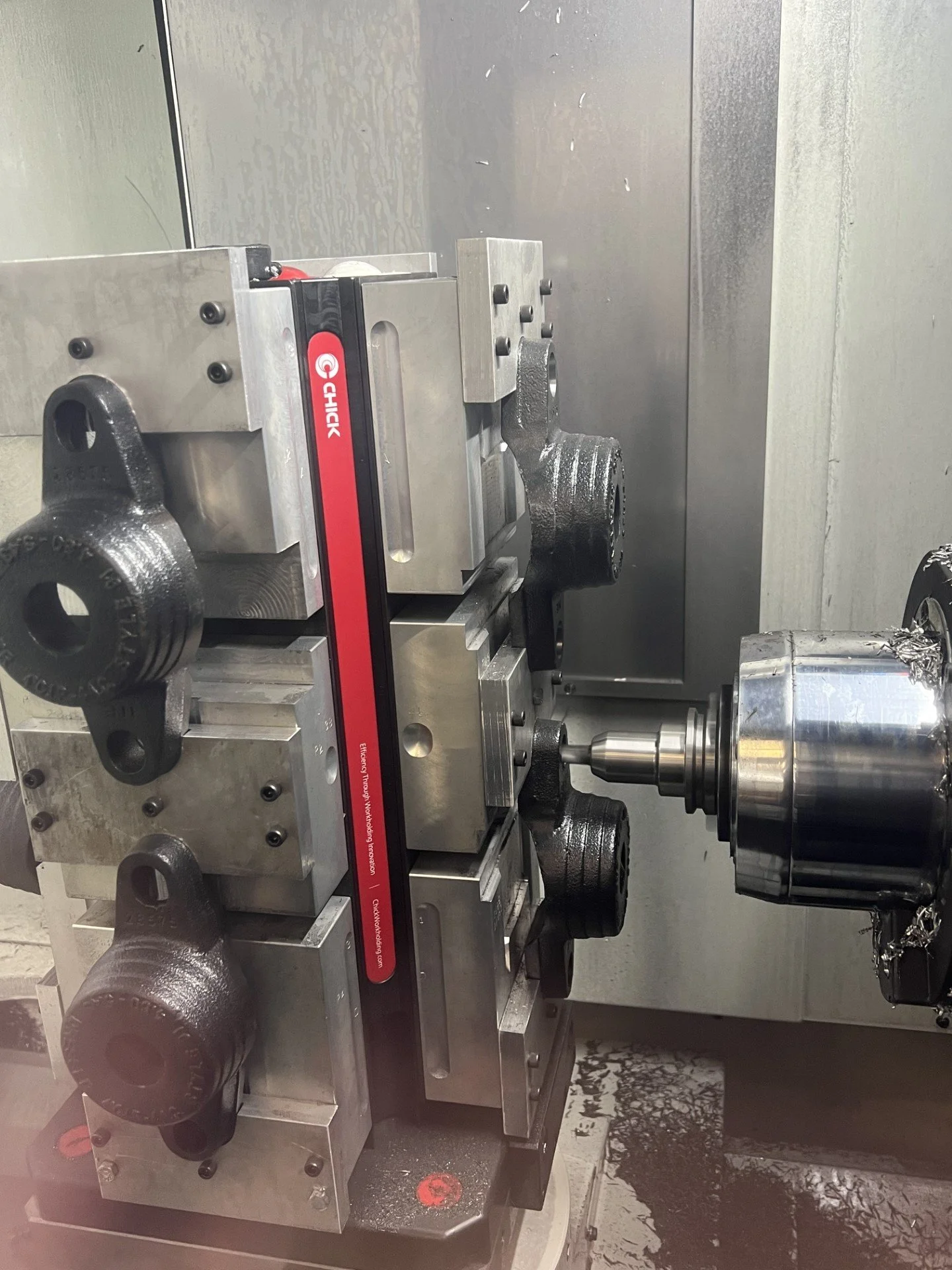

With the new equipment, we were able to process the entire part in one operation. We modified Chick Workholding tombstone vices to be able to hold several parts at once and reach all sides of the part. The machine time was greatly reduced and with pallet changing, all handling of the part is done while the machine is running. We were able to work with our customer to reduce the cost of the part by 40% despite recent material increases.

High Volume CNC Horizontal Milling for Oil and Gas Valves

We were able to modify our tombstone jaws to hold the external shape of this part, allowing us to mill the part.

Our new CNC horizontal milling equipment allowed us to take on a new project for an oil and gas valve OEM that we previously wouldn’t have been able to be competitive with. The project required us to mill a slot in a cast valve body with order quantities exceeding 10,000pcs. The quantity and minimal machining work required dictated that we needed to make the process as automated as possible. Before we had invested in the Kitamura Horizontal Machining center, we would have been left to do these on one of our CNC Vertical Mills. While the machining time would have very similar per part, the machine would have to wait for an operator to change parts at the end of each cycle.

We were able to use our Chick Tombstone vices to hold 8 parts at once to quickly mill these and we utilized our pallet changer to have our operator changing out parts while the machine was milling. The efficiency of our machining on our new equipment allowed us to provide the part at a cost significantly lower than we ever would have been able to before the investment. This allowed our company to earn a new project and helped our customer to reduce cost and lead time for their product. A true win-win!

These are just two examples of how we have utilized our new equipment to serve our customers. We have been able to offer reduced pricing as well as take on new projects for several of our customers already and we are ready to do such for more customers. If you need production milled valve components, we encourage you to request a quote today!